-

-

Notifications

You must be signed in to change notification settings - Fork 22

Belt Installation Y Axis

undoz edited this page Sep 2, 2024

·

19 revisions

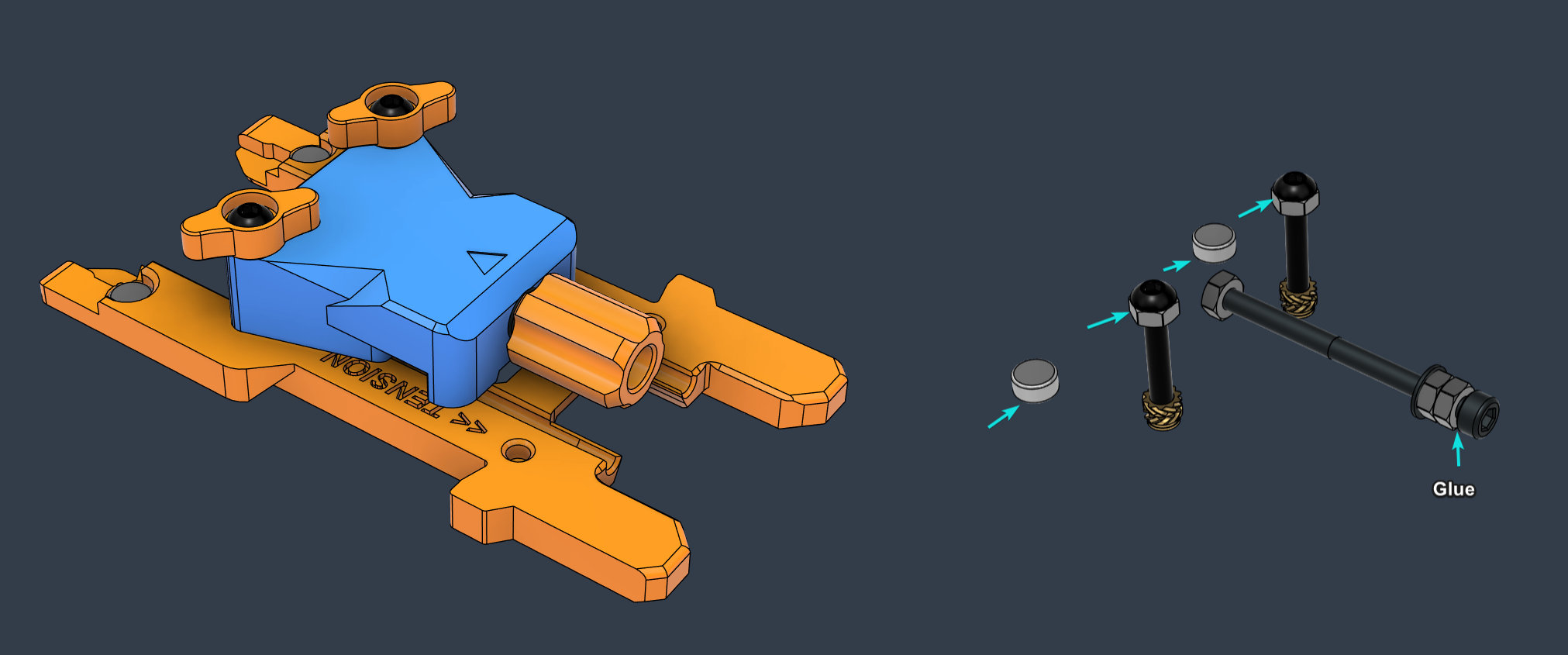

Belt Clamp

| Type | Item | Quantity |

|---|---|---|

| Hex Nut | M3 | 2 |

| Screw Button Head | M3 8mm | 2 |

Belt Tensioner

| Type | Item | Quantity |

|---|---|---|

| Hex Nut | M3 | 4 |

| Screw Button Head | M3 12mm | 2 |

| Screw Countersunk | M3 10mm | 2 |

- Glue the hex nuts into the sockets of the belt clamp (Left) to prevent them from falling during installation

- Don't worry if the bottom part cracks or breaks. It is not structural, and only meant for ease of assembly

- Attach a screw to the hex nut and push it inside the tensioner (right). Some force might be needed.

Tip

-

The rear belt clamp can be installed before mounting the carriage onto the mounts

-

To pull the belt though the carriage hole once the carriage is installed, you can insert a narrow piece of tape though the carriage hole and then tape it on both sides of the belt to pull it though.

Pull the belt though.

Y Belt Tool - For Setup and Tightening

- One side helps with pre-tensioning the belt and securing the nuts in place for attaching the top tensioning plate

- The other side is helps aligning the hex key for tensioning the belt with the bed mounted

Hardware

| Item | Quantity |

|---|---|

| Heat Insert M3 Short 5x4 | 2 |

| Nut Hex M3 | 7 |

| Magnet 6x3mm | 2 |

| Screw Button Head M3 20mm | 2 |

| Screw Socket Head M3 40mm | 1 |

- Loosen the grub screws of the front Y stepper motor pulley

- Insert the hex nuts into the tensioning tool and set it in possible

- If it's blocked by the carriage, lift the front of the carriage a bit until it clears it

y_belt_a1.mp4

- Pull the belt tight and hold it with one finger on the carriage

- Set the belt onto the tool and loop it though the hole and under the edge of the carriage

- While holding it, attach the top part of the pre-tensioning tool and lock it in place.

- Rotate the tensioning knob until the belt is tight

y_belt_a2.mp4

- Insert the adjustable belt clamp (make sure the screws are flush with hex nuts)

- Secure the top plate

y_belt_a3.mp4

- Remove the tensioning tool

- Move the carriage back and adjust the belt tension by using the two screws in adjustable clamp

- Note: You don't have to use the tensioning like I do in the video. That side of the tool is mainly intended for tensioning with the bet attached.

y_belt_a4.mp4

- Finish by performing a step sync procedure and secure the grub screws of the front pulley.

Tip

- A piece of Kapton tape can be added on top of the tensioner block to ease the movement and apply more pressure.

- A strip of PVC tape can be added on the CF carriage where the back of the belt touches to increase pressure and friction.

- Due to the heat proximity of the assembly, it is highly recommended to replace the printed top tensioner plate with a ~1.5mm drilled PCB (FR4) plate, or aluminum. Make sure the screws have enough clearance from the heater, not to damage it and cause a short.

A custom FR4 PCB Plate design can be found in User_Mods: Y Tensioner PCB Retailer Plate

- Please refer to the Tuning Guide for setting the belt tension and stepper sync.